Model | GS016 | GS3016 | GS4016 |

Max work piece size (L×W) | 2000X1600mm plate or Φ1600mm flange | 3000X1600mm plate or Φ1600mm flange | 4000X1600mm plate or Φ1600mm flange |

Max. thickness of work piece | 15~100mm (hydraulic clamp), 120mm (T-slot) | ||

Clamping type | Hydraulic clamp, T-slot | ||

Drill unit type | sliding table, servo control | ||

Drill head quantity | 1 | ||

Max drill diameter | Ф40/Ф50mm | ||

Taper hole of spindle | BT40/BT50 | ||

Spindle motor power | 18.5/22 kW | ||

Spindle speed | 30~3000r/min | ||

Servo motor power of X axis | 1.5 kW | ||

Servo motor power of Y axis | 1. 5 kW | ||

Servo motor power of Z axis | 3 kW | ||

CNC system | SIMENS 808D | ||

CNC axis quantity | 3 | ||

Position precision | ≤±0.08mm | ||

Repeated position precision | ≤±0.04mm | ||

Overall size | About 4.5x3.9x3.2m | About 5.5x3.9x3.2m | About 6.5x3.9x3.2m |

Weight | About 11 tons | About 12 tons | About 13.5 tons |

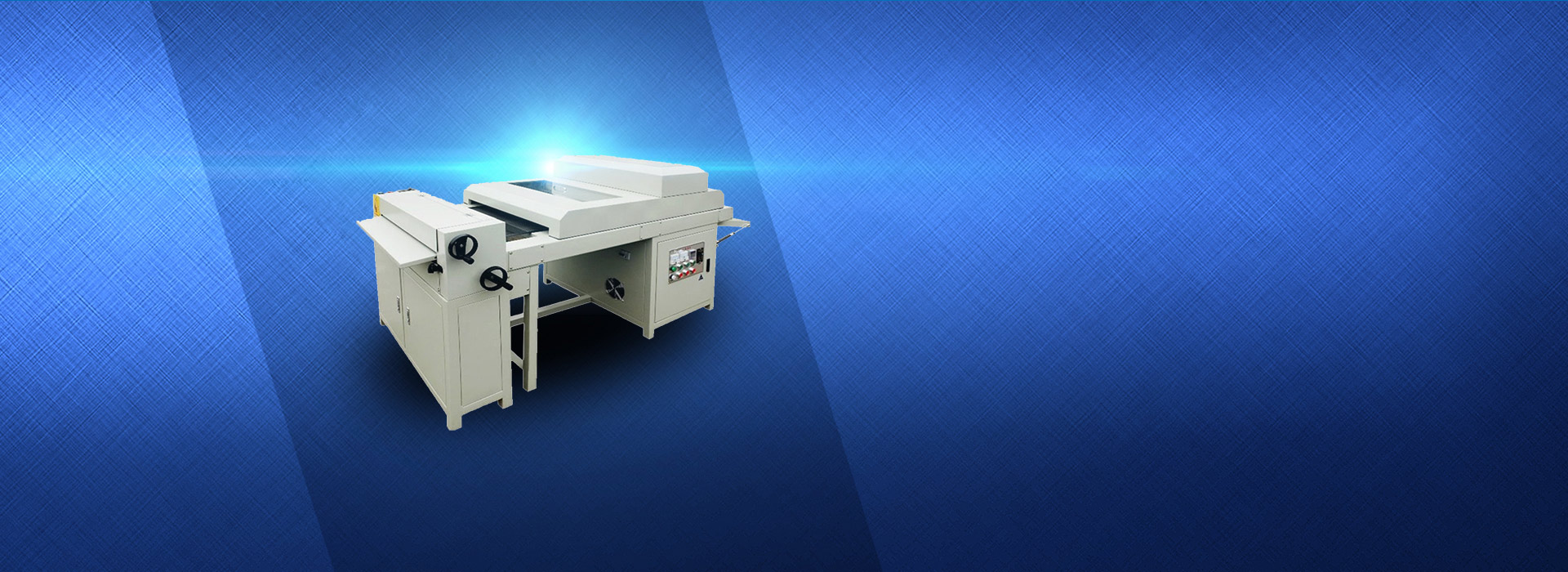

Application:.

This machine is the automatic special equipment used for drilling, tapping, milling steel plate, flanges,

tube sheets, mainly in the field of steel structure, boiler, heat-exchanger and so on. This machine can drill through hole, blind hole and ladder hole. It also can be used milling groove.

Product Feature:

1. The machine adopts the gantry moving structure, the longitudinal movement (X axis), the lateral movement (Y axis) and the vertical movement of the drilling power head (Z axis), which are all driven by the servo motor through the precision ball screw. It can automatically, accurately and quickly locate and automatically complete the drilling process. The drilling accuracy and speed are greatly improved.

2. The machine adopts Siemens CNC system. The upper computer is equipped with automatic programming software and machine monitoring software, which can directly convert AUTOCAD graphic files into machining programs.

3. There are 12 hydraulic clamps and T slots for fixing workpiece, easy to operate, also save time, improve production efficiency.

4. Adopt BT40/BT50 internal cooling spindle, carbide internal cooling drill can be used with high precision. Equipped with a gas-liquid pressurized knife cylinder, it is very convenient to load and unload tools. The spindle is driven by a high-power spindle variable frequency motor through a timing belt.

5. The configuration of the machine, like cnc system ball screws, linear guides, main electrical parts, servo motors, hydraulic valves, etc., are famous brand.

中文

中文 English

English